| Model predictive loss-in-weight controller / Vibratory feeder |

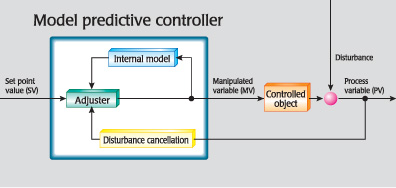

Model predictive control Model predictive control |

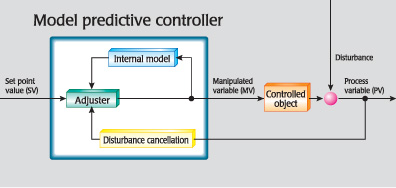

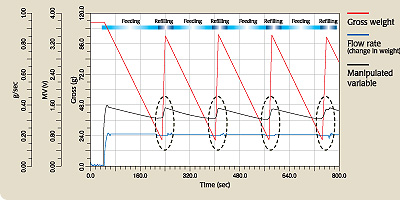

Model predictive control is a method of process control to determine a manipulated variable, which enables a process variable to reach a set point by predicting future moves in a process using models of the controlled object's

behavior. The internal model is used to predict if any deviation from the set point will occur in the immediate future when process control is continued with the current manipulated variable. If a deviation is predicted, an djusted manipulated variable is output and sent to the controlled object. Unlike PID control whichimplements a correction after a control deviation occurs, model predictive control |

|

predicts a deviation in advance using a model of the system's behavior to enable stable process control while avoiding hunting (unstable movement). The greatest advantages of model predictive control are process control stability, disturbance cancellation function, improved response to changes and improved set point following capability, as well as a high tolerance to the influence of changes in a process.

Model predictive control can be applied to a process that is too difficult to control with general PID control. Its stable control enables improvement of maintenance productivity by minimizing energy waste and excess load on the driving part. |

|

| |

Auto-tuning function for controlled object modeling Auto-tuning function for controlled object modeling |

| Setting of the AD-4826 control parameters is not difficult. It uses its auto-tuning function to automatically model the behavior of a controlled object and controls the process using the model. Auto tuning is also very simple. Just connect the AD-4826 controller to a feeder, start feeding with a material and then implement the 4 steps of the step response method during the feeding process to obtain dead time plus first-order lag elements as transfer function. The AD-4826's auto-tuning function and control function apply to a linear system as well as to a nonlinear system, which is too difficult to control with PID control. This auto-tuning function requires no special techniques and enables easy modeling of a controlled object in a short period of time. |

|

|

| |

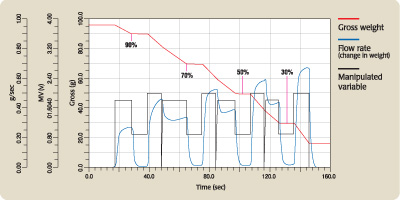

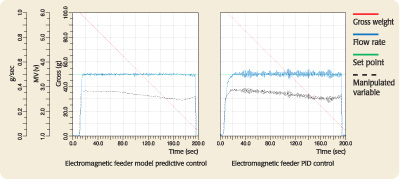

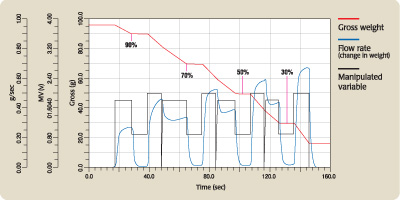

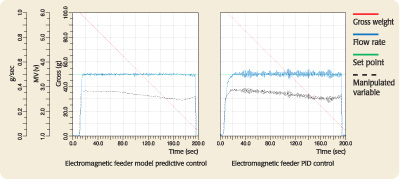

Stable control minimizing energy loss and deterioration of actuator Stable control minimizing energy loss and deterioration of actuator |

| Since PID control implements the correction of a manipulated variable after the occurrence of a control deviation, there is a large amount of change in the manipulated variable as well as in the process variable. Therefore, with PID control, the extra load acts upon the actuator and causes energy loss. On the other hand, model predictive control can provide stable control, minimizing hunting (unstable movement) to improve energy efficiency and offers excellent maintenance productivity. |

|

|

Disturbance (vibration) cancellation function Disturbance (vibration) cancellation function |

| When the AD-4826 detects a disturbance (vibration) during continuous feeding, its disturbance (vibration) cancellation function works to cancel the influence of this disturbance (vibration). It promises stable continuous feeding by preventing a feeding outage, which is caused by disturbance, as well as an excess increase or decrease in flow rate. |

| |

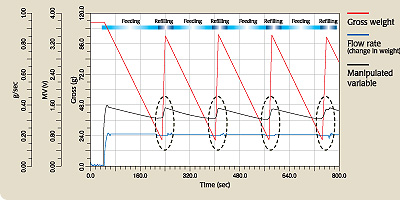

Map-based control function for continuous feeding during refilling Map-based control function for continuous feeding during refilling |

| To continue continuous feeding, it is necessary to refill the feeder with material when its content is reduced. The AD-4826 is equipped with a map-based control function to allow the feeder to be refilled during continuous feeding. The map-based control function stores in memory plotted data of the correlation between manipulated variables and weight values, which are measured during continuous feeding, to accurately control the manipulated variables while checking weight values with the weight sensor when refilling the feeder. Therefore, the AD-4826 enables highly accurate continuous feeding even while the feeder is being refilled. |

|

|

| |

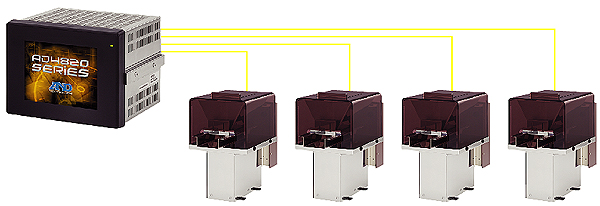

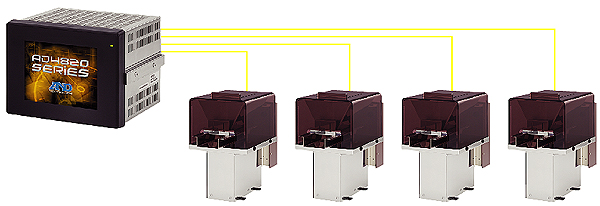

Controlling up to 4 feeders Controlling up to 4 feeders |

|

|

| |

Model predictive feeder controller applicable for existing screw feeders, circle feeders, table feeders, etc. Model predictive feeder controller applicable for existing screw feeders, circle feeders, table feeders, etc. |

| The AD-4826 can implement model predictive control with a screw feeder, circle feeder, table feeder or rotary feeder that has been controlled with PID control. |

|

GUI screen allowing intuitive operation (PDF 158KB) GUI screen allowing intuitive operation (PDF 158KB) |

| |

| Specifications |

Feeder controller specifications Feeder controller specifications |

| Model |

AD-4826 |

| CPU |

SH4 |

| OS |

RTOS |

| SDRAM |

64MB |

| Compact flash memory |

64MB |

| Option slots |

4 |

| Display |

5.7 inch STN color liquid crystal

Backlight luminance half life: 75,000 hours typ.

Touch panel: Analog film |

| Standard interface |

Serial interface: Full duplex RS-232C/ full duplex RS-485 switch

USB1.1 port

LAN 10Base-T

Non-polar semi-conductor relay (controller startup status output) |

| Power |

AC85V - 250V, 50/60Hz, approx. 30VA |

| Ambient temperature |

0 - 40°C |

| External dimensions (WxHxD) |

192 x 144 x 191mm (including protruding part) |

|

|

| |

Load cell input specifications Load cell input specifications |

| Input sensitivity |

0.15µV/D or over |

| Zero adjustment range |

0mV - 25mV |

| Load cell applied voltage |

emote sensing function

Up to 8 load cells (350Ω) can be connected to a channel.

(If 4 load cell input modules are installed on a slot, up to 4 load cells can be connected to a channel.) |

| Temperature coefficient |

Zero point: ±0.1µV/°C max.

Span: ±8ppm/°C max. |

| Nonlinearity |

±20ppm max. |

| Measuring range |

±37mV min. |

| A/D conversion method |

24 bit delta sigma method |

| Internal resolution |

Approx. 5,700,000 counts |

| Maximum display resolution |

Approx. 1,000,000 counts per 1mV/V |

| Sampling rate |

6.25 - 1920 times /second |

|

|

| |

External input/output boards specifications External input/output boards specifications |

Analog input interface board

(4 modules can be installed on a board) |

Applicable modules |

AD-4820-02 (Load cell input) |

AD-4820-10

Standard I/O board |

32 standard digital input points, 32 open collector output points,

2 pulse input points |

AD-4820-14

Analog output interface board

(4 modules can be installed on a board) |

Applicable modules |

AD-4820-15 (4 - 20mV output)

2 channels per module

AD-4820-16 (0 - 10V output)

2 channels per module |

|

|

| |

Vibratory feeder AD-4826-30G/200G/500G Vibratory feeder AD-4826-30G/200G/500G |

| Model |

30G |

200G |

500G |

| Maximum capacity |

30g |

200G |

500G |

| Minimum display |

0.01g |

0.1g |

0.1g |

| Flow rate setting range |

0.1g - 4g / sec. |

1.0g - 30g / sec. |

5.0g - 40g / sec. |

| Batch accuracy (standard deviation) |

±0.02g or less |

±0.2g or less |

±0.6g or less |

|

|

| |